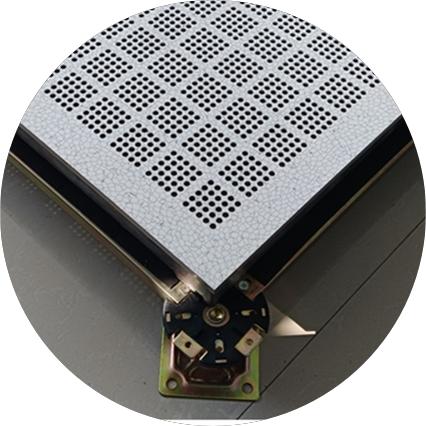

Aluminum Perforated Raised Access Floor Antistatic Conductive

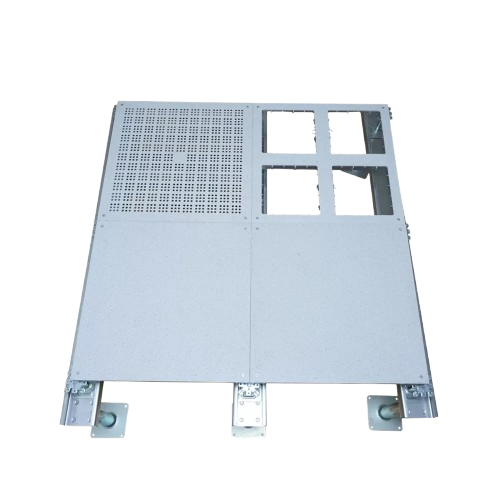

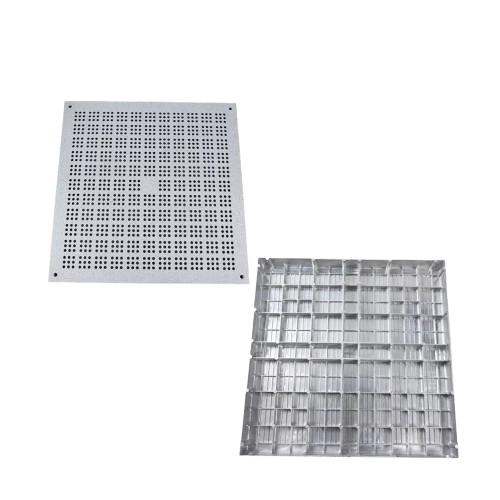

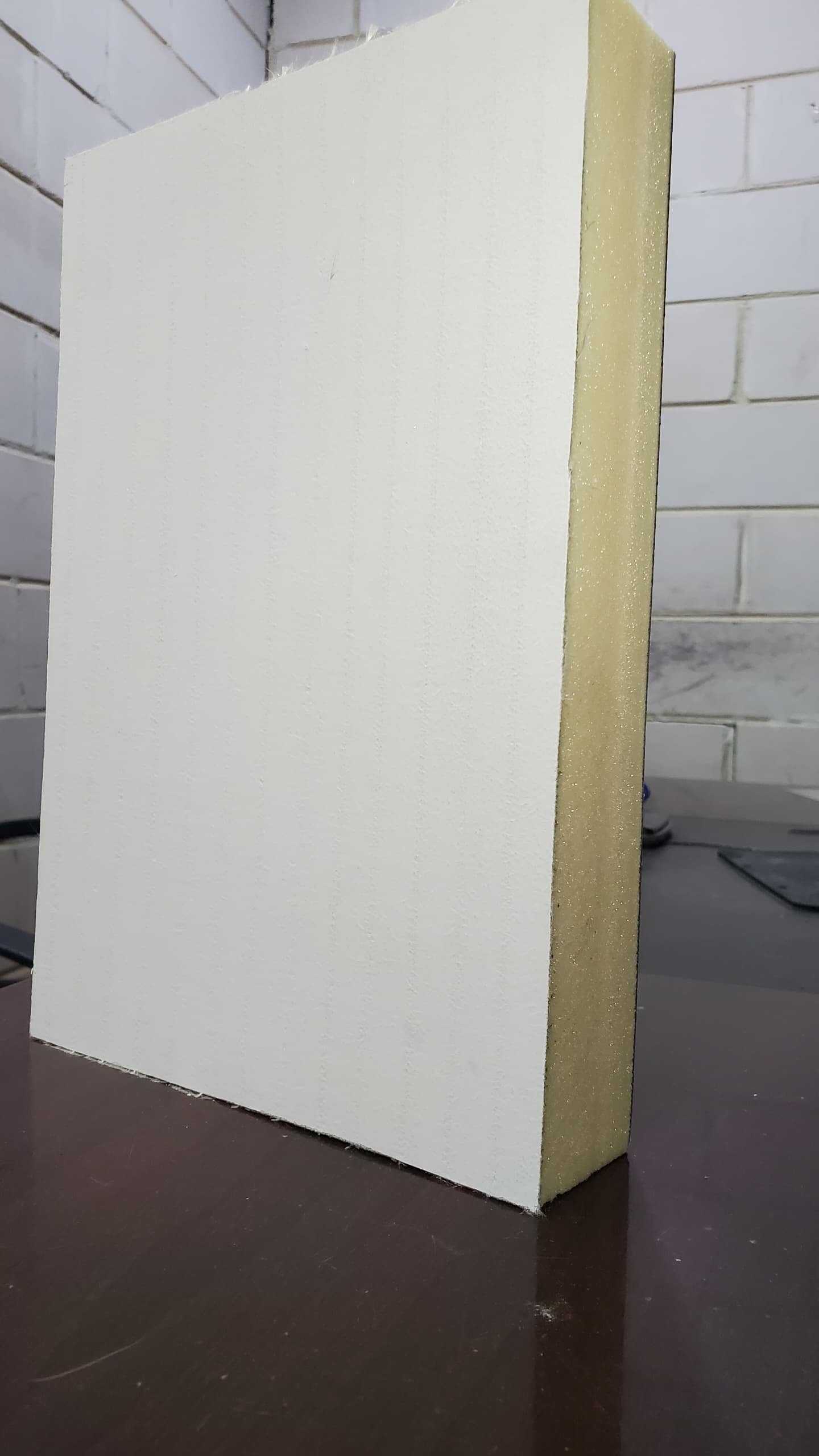

Structure of Aluminum perforated antistatic raised access floor

How to make aluminum antistatic access flooring ?

-Components of aluminum antistatic raised access flooring

Main material: The main material of aluminum flooring is aluminum alloy, and MAJET company uses high-quality die-cast aluminum material ADC12. This material has a high aluminum content, good mechanical properties, high dimensional stability and is easy to cast. At the same time, it has the advantages of corrosion resistance, microbial resistance, light weight, and high load-bearing capacity. Because of these properties, aluminum is one of the most economical and suitable materials for structural use in both commercial and military sectors.

Surface treatment: The entire aluminum floor can be epoxy sprayed or nickel-chromium plated. anti static raised access floor anti-static raised access floor

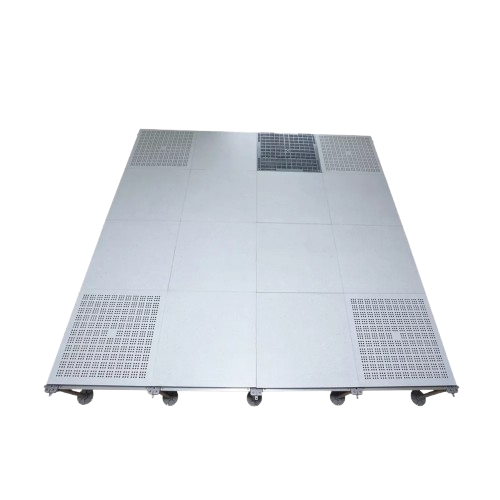

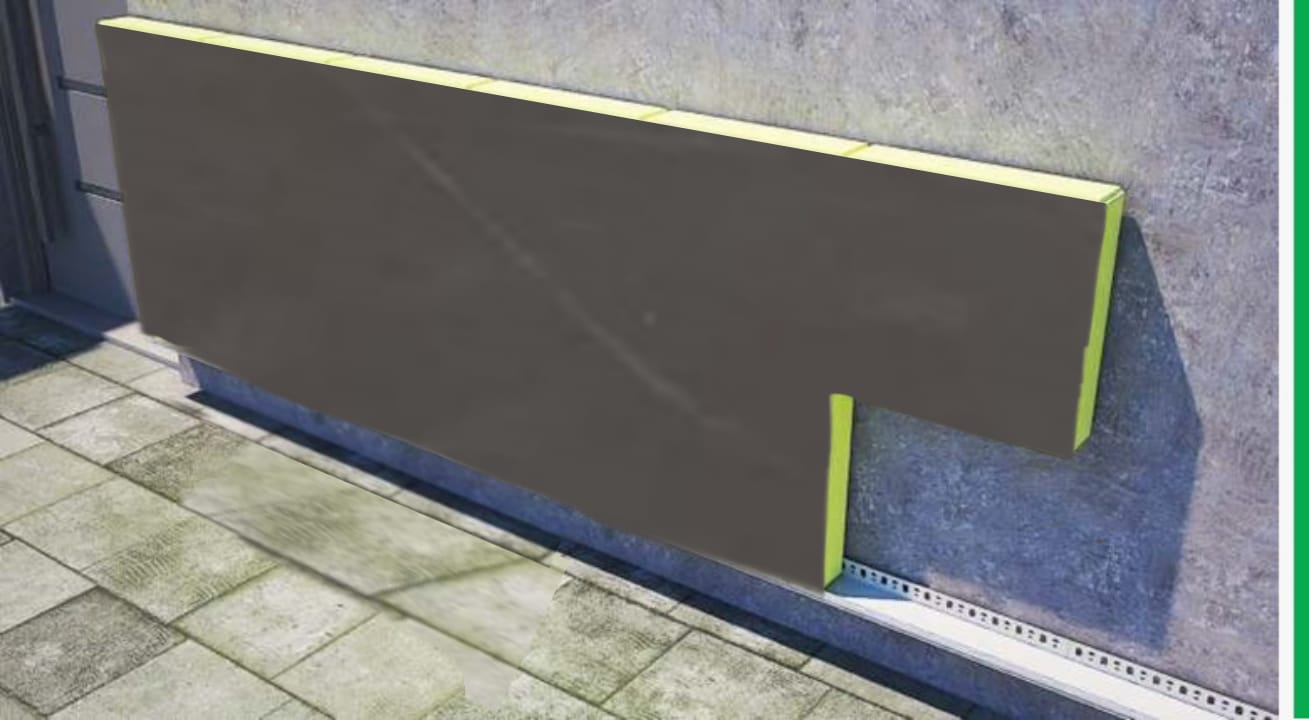

Adjustable overhead systems: Aluminum floors, like steel floors, can be used with matching overhead systems. These elevated systems can not only raise the floor, but can also be combined with various trunking systems and the equipment installation requirements of the site to create different design solutions. MAJET can provide steel bracket systems and aluminum bracket systems, and the surface of the bracket system can be cold-dip galvanized, hot-dip galvanized, chrome plated and other processes to meet the higher-end needs of customers. raised access floor load capacity of perforated flooring or Aluminum flooring system is very good.

MAJET has a history of processing aluminum flooring for more than 30 years, and now has a full set of highly mechanized equipment, automatic robotic arms and other equipment. It can effectively ensure the dimensional stability and high-efficiency production of products

Underfloor System aluminum raised access floor

1. Galvanized Steel pedestal system , made of Galvanized steel.

2. Aluminum made pedestal system .

Galvanized Steel Pedestal

Galvanized Steel Pedestal

Aluminum Pedestal

Aluminum Pedestal

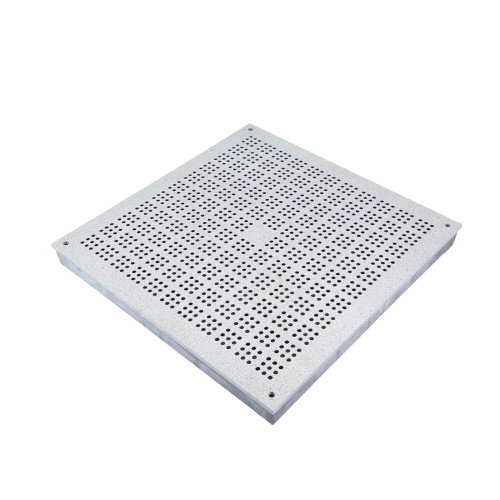

Specification of Aluminum Solid raised access floor

Installation Process of Aluminum perforated raised access floor

Installing raised floors involves a systematic approach to ensure stability and functionality. The process includes preparing the subfloor, assembling the support structure, and securing the panels in place.

Step-by-Step Guide to Installing Raised Floors

Subfloor Preparation:

Ensure the subfloor is clean, level, and free from debris.

Grid Assembly:

Construct the support grid according to the design specifications.

Panel Installation:

Secure the panels onto the grid, ensuring a snug fit.

Finishing Touches:

Complete the installation with trim and edge pieces for a polished look.

Installation tools of raised floor

Raised floor electrical screwdriver

Features of Aluminum perforated raised access flooring

1. Light weight but high load-bearing capacity

2. Use conductive and static-dissipative coverings and coatings for anti-static properties

3. Corrosion-resistant, water-resistant, fire-resistant, long service life

4. Standard floor components, high dimensional accuracy, easy construction and easy to use

5. High load-bearing elevated structure design, adjustable installation height

6. Perforated panels and grilles available in various open area percentages

7. Environmentally friendly materials, recyclability

8. Panel colors, materials, and functions can provide a variety of choices

Production process of Aluminum perforated raised access floor

Process:Cutting-forming-welding-phosphating and spraying-filling cement-drying