TONGUE & GROOVE Calcium Sulphate Raised Floor interlock

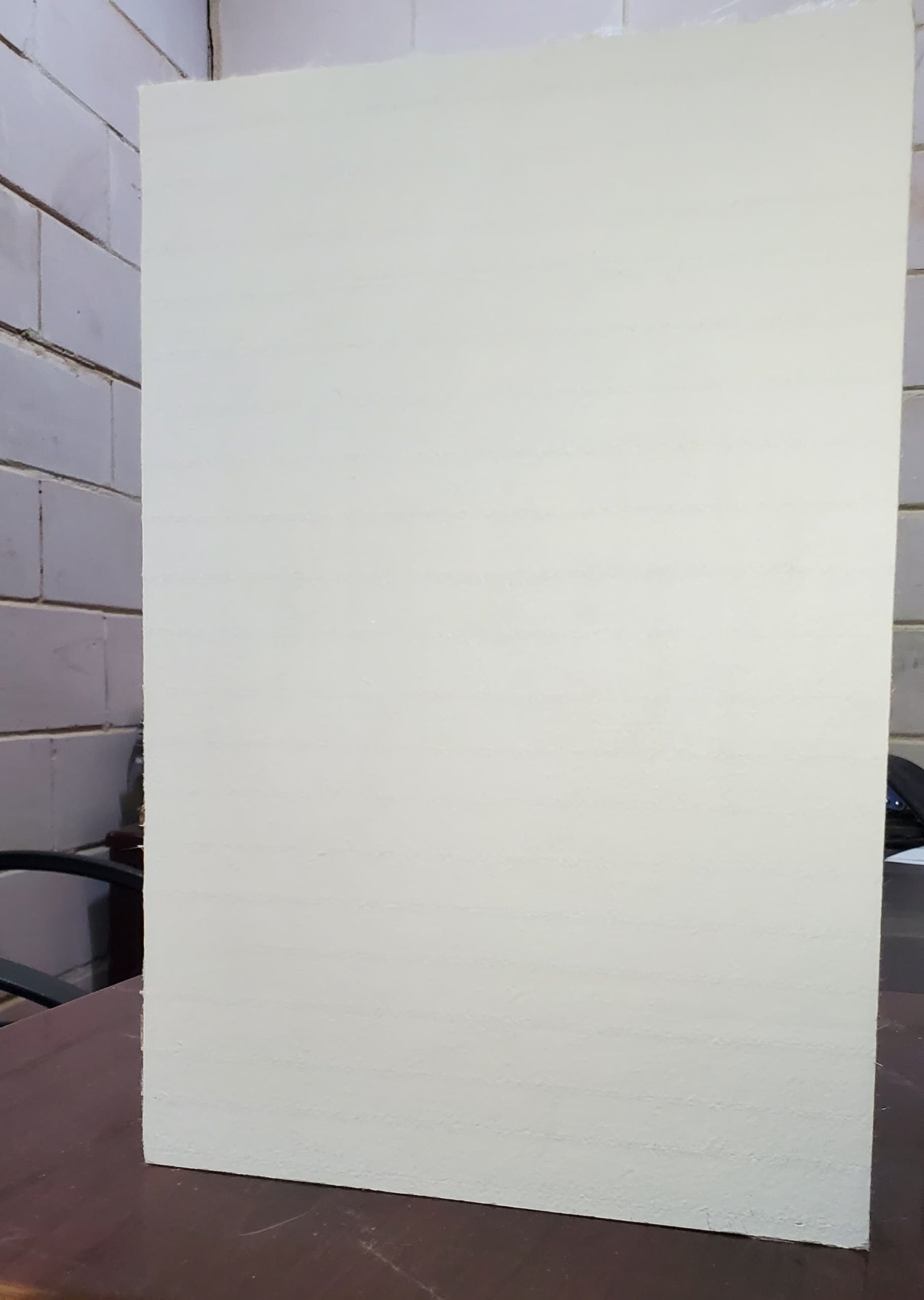

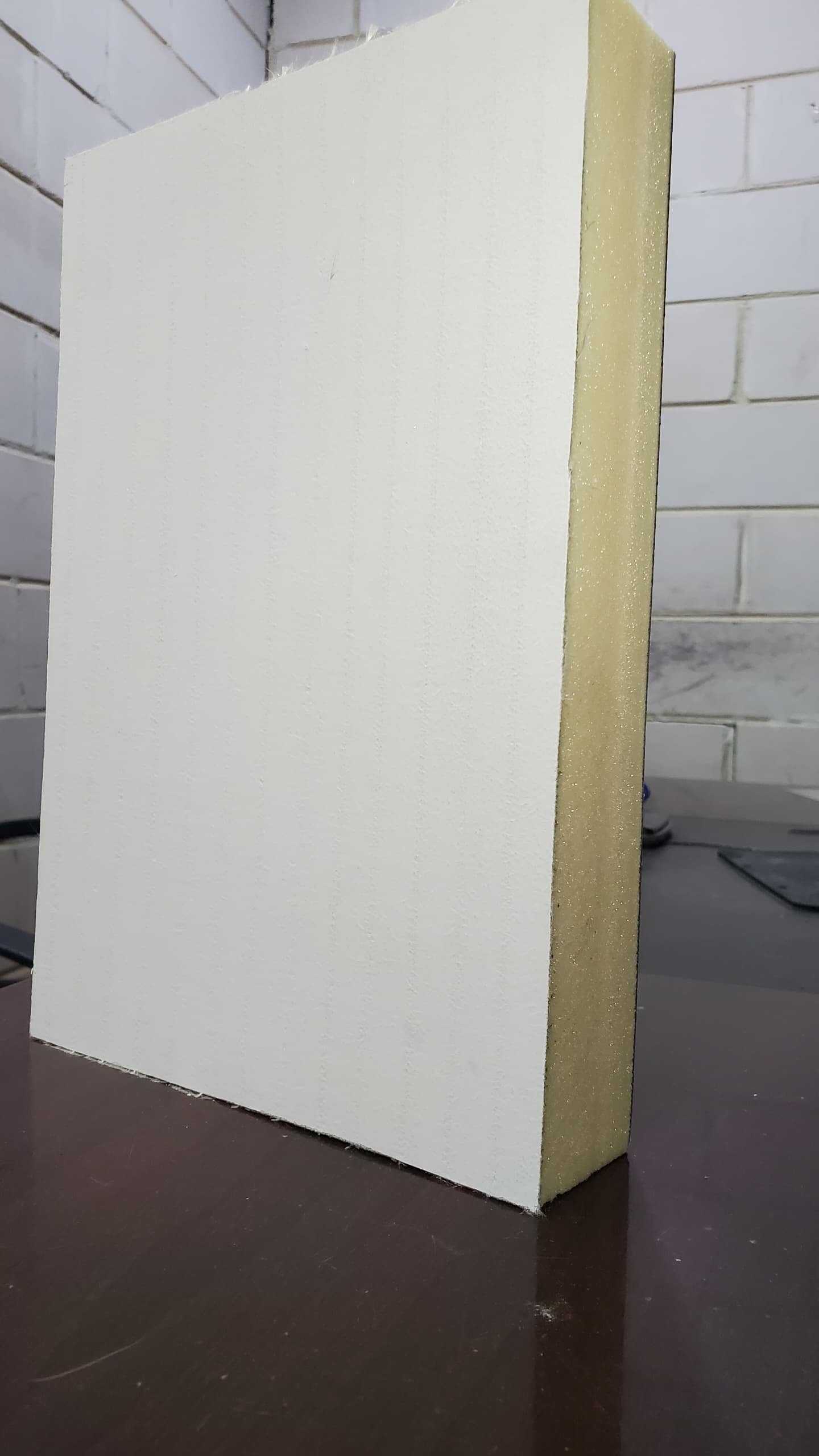

Structure of tongue &groove Calcium Sulphate Raised Floor/Interlock floor

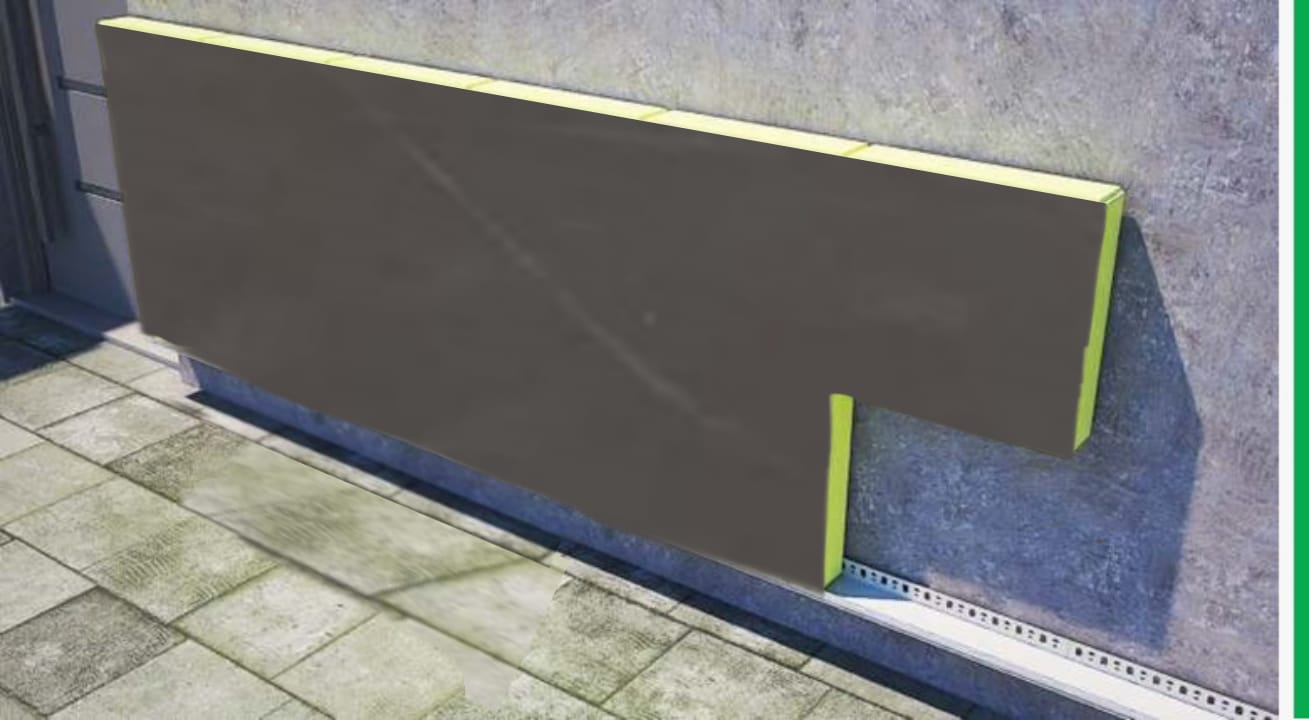

Tongue and groove panel can interlock two panels edges, so that we can create a real floor slab.

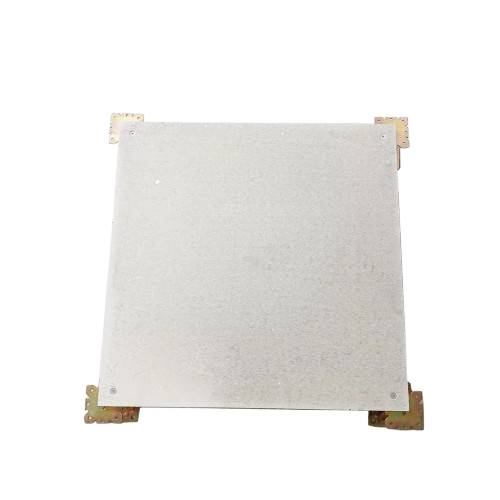

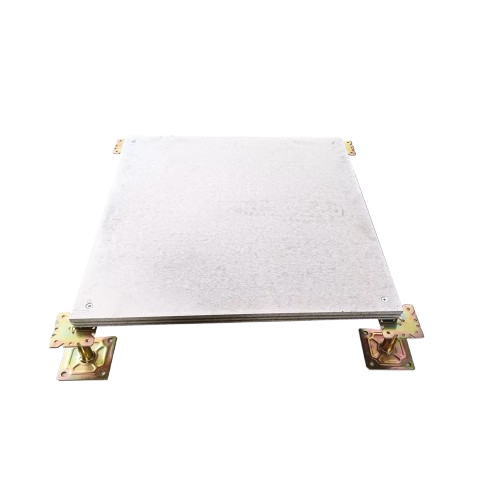

The raised access floor panel are made of calcium sulphate core,top bare, bottom stick with galvanized steel sheet .The panel edges feature an interlocking profile.four corner open holes to use screw fix panel with pedestal. It used with pedestals as support system. or use pedestal and stringers at same time.

Specification of tongue &groove calcium sulphate raised floor

10000Timesheavy duty600*600≥1012≥4498≥458670≥13494≥2329435962959extra heavy duty600*600≥1258≥5595≥570670≥16797≥3308444983596

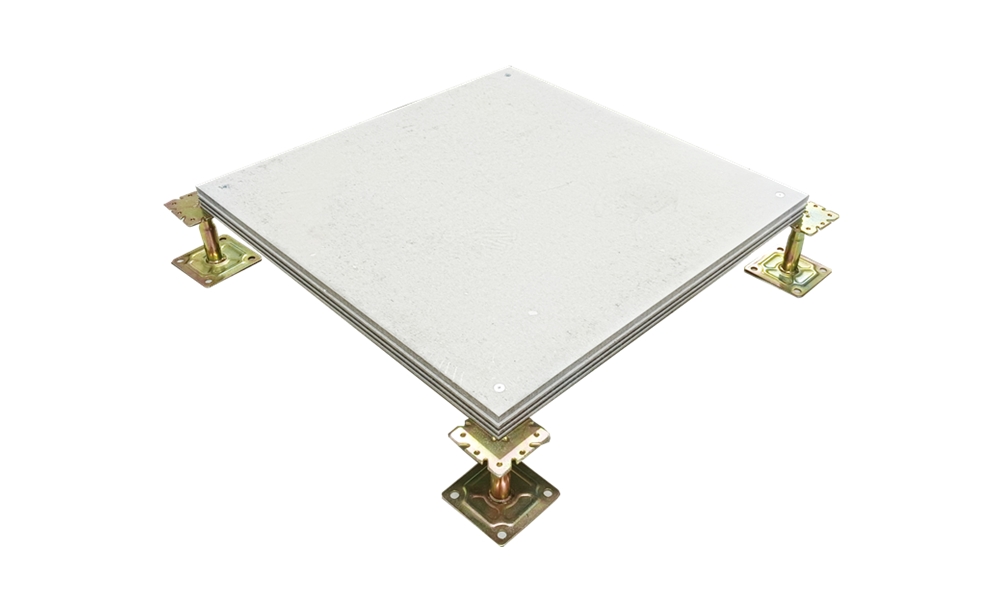

Support system of tongue&groove calcium sulphate raised floor

use Galvanized steel pedestal

Installation Process of tongue&groove calcium sulphate raised floor

Installing raised floors involves a systematic approach to ensure stability and functionality. The process includes preparing the subfloor, assembling the support structure, and securing the panels in place.

Step-by-Step Guide to Installing antistatic calcium sulphate Raised Floors

Subfloor Preparation:

Ensure the subfloor is clean, level, and free from debris.

Grid Assembly:

Construct the support grid according to the design specifications.

Panel Installation:

Secure the panels onto the grid, ensuring a snug fit.

Finishing Touches:

Complete the installation with trim and edge pieces for a polished look.