Encapsulated woodcore Raised Floor-MAJET

Installation Vedio of encapsulated woodcore Raised Floor

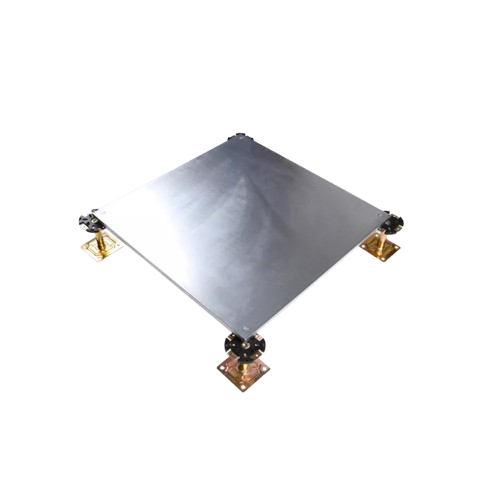

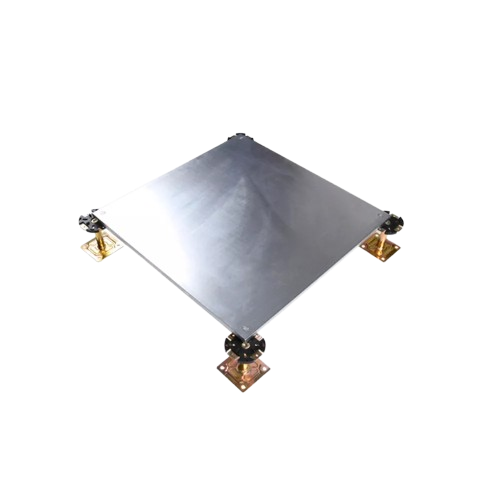

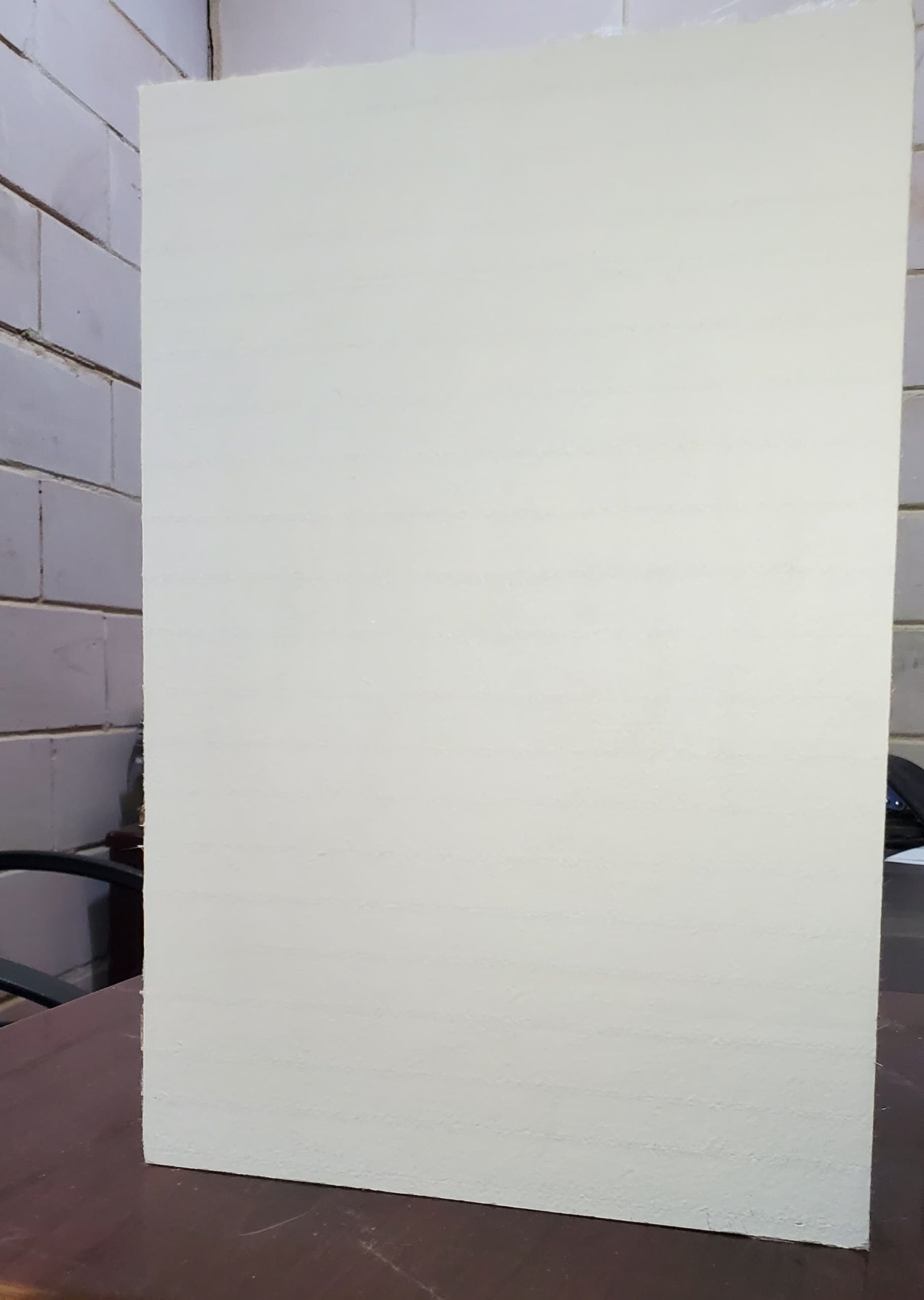

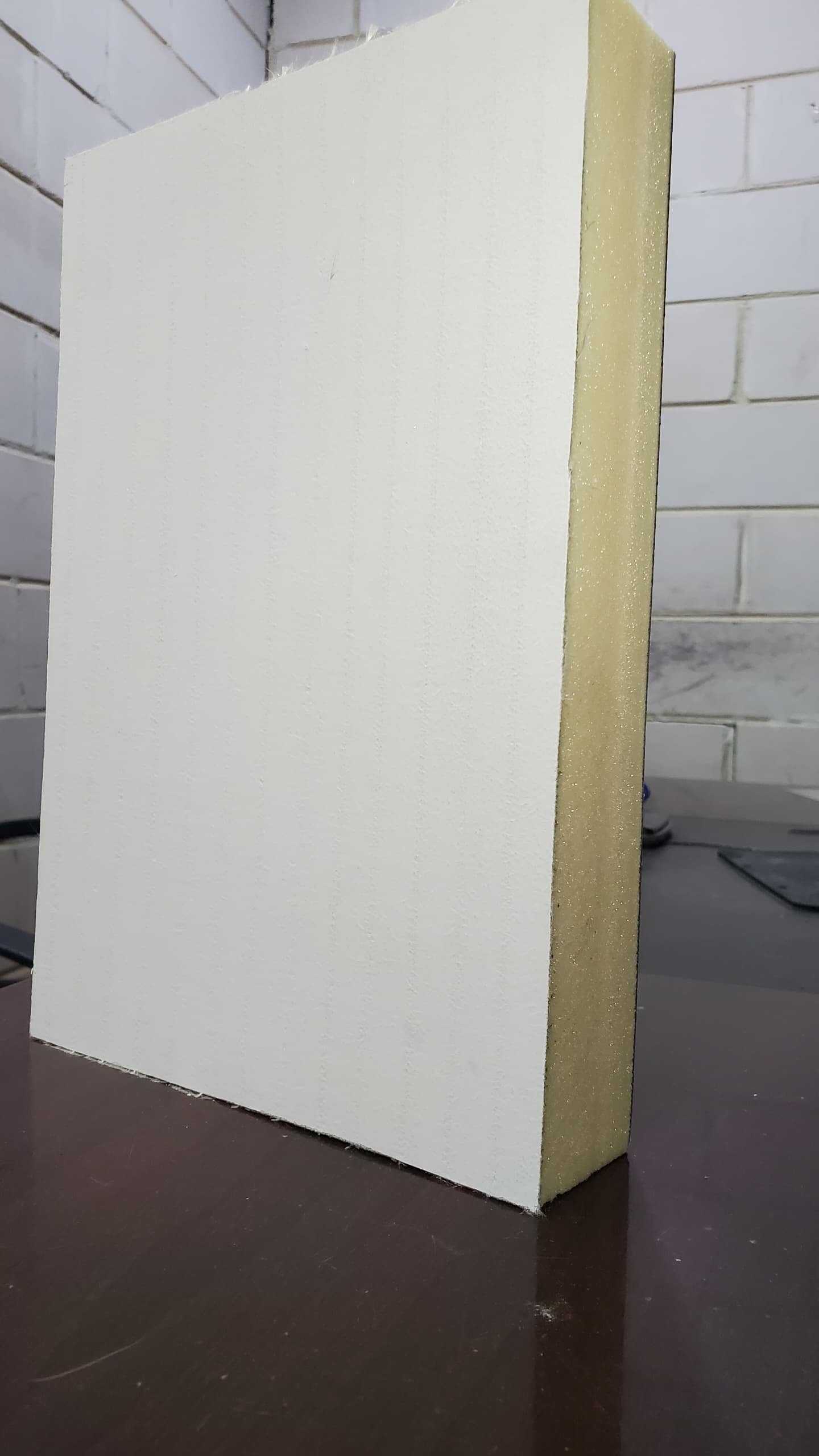

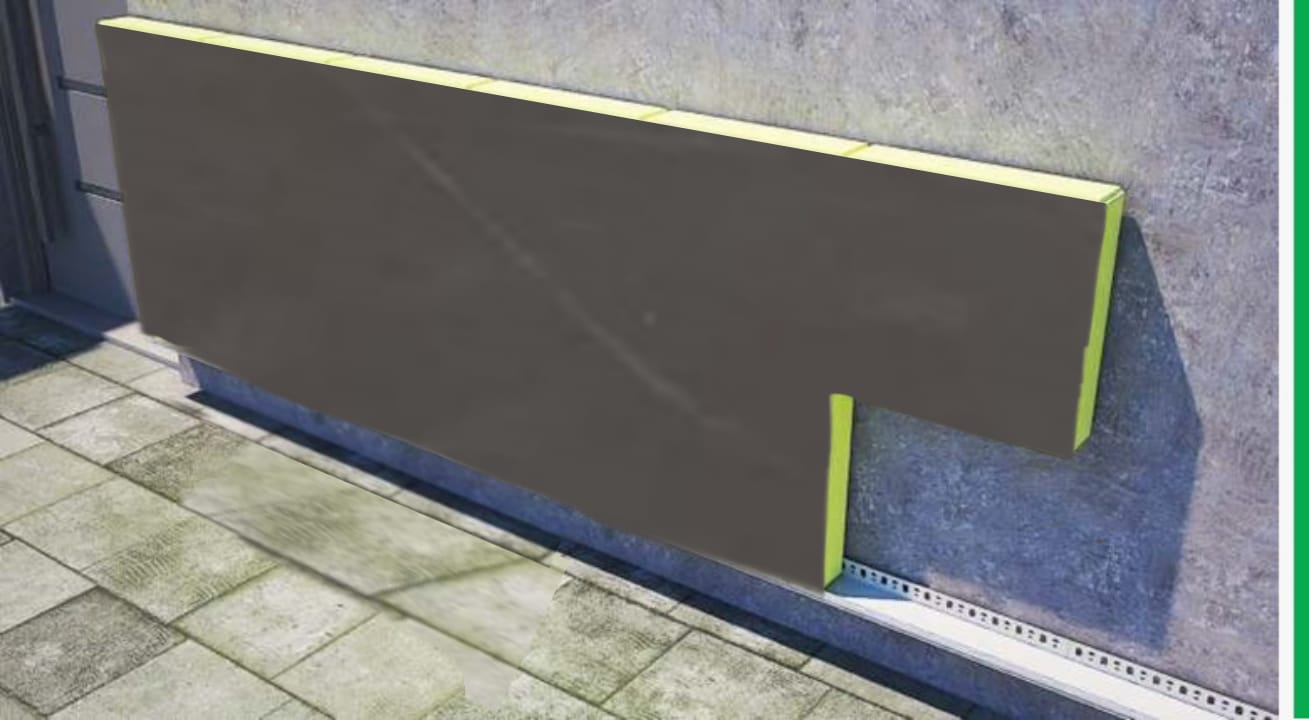

Structure of Encapsulated woodcore Raised Floor

The woodcore raised floor panel is made of high density chipboard.Galvanized steel sheet sealed on all sides,Various surface finishes available.

Specification of Encapsulated woodcore raised floor

10000TimesLight duty600x600≥2990≥300670≥8890≥1250022151548Medium duty600*600≥3596≥360670≥10799≥1979629592215Heavy duty600*6004498≥450670≥13494≥2329435962959

Installation Process of Encapsulated Woodcore raised floor

Installing raised floors involves a systematic approach to ensure stability and functionality. The process includes preparing the subfloor, assembling the support structure, and securing the panels in place.

Step-by-Step Guide to Installing encapsulated woodcore Raised Floors

Subfloor Preparation:

Ensure the subfloor is clean, level, and free from debris.

Grid Assembly:

Construct the support grid according to the design specifications.

Panel Installation:

Secure the panels onto the grid, ensuring a snug fit.

Finishing Touches:

Complete the installation with trim and edge pieces for a polished look.

Installation tools of encapsulated woodcore raised floor

Features of encapsulated woodcore raised floor

1.Light weight,small noise when working

2.Dimension accuracy with nice interchangeability

3.Stronger loading capacity,fire resistance B2 and excellent anti-static properties.

4.Good sealing and water-proof

Production process of encapsulated woodocre raised floor

Process:molding-edging-laminate-edge triming-packing

Related production of encapsulated woodcore raised floor

Laminated raised floor

Calcium sulphate raised floor

Woodcore raised floor

Aluminum raised floor

Perforated raised floor

Applications of encapsulated woodcore raised floor

Office

In modern office design, raised floors contribute to a clean and organized appearance while accommodating the complex wiring systems necessary for today’s technology-driven workplaces.

Data center

Data centers rely on raised floors to manage the extensive cabling required for servers and networking equipment. The improved airflow also helps in maintaining optimal temperatures for electronic components.

Cleanroom Environments

Industries with stringent cleanliness requirements, such as pharmaceuticals and biotechnology, utilize raised floors to create controlled environments free from dust and contaminants.

Educational Institutions

Schools and universities leverage the flexibility of raised floors to accommodate evolving technologies in classrooms and laboratories.

Comparison of different raised floors

NOTE:

1.Majet raised access floor has continuous product data improvement.It reserves the right to change type design and specifications without notice.

2.A—Most advantage,E—Least advantage

3.The comparison is based on the raised access floor panels of same concentrated loading grade.

Comparison of different raised floor downlaod

Our company about raised floor

MAJET raised floor is a leading manufacturer and exporter in China, supplying raised floor system, data center products, underfloor air conditioning and underfloor wiring. We have over 60,000 square meters plant and 200 workers and over 35 years experience in industry.

Majet raised floor caltalogue download

Quality control of encapsulated woodcore raised floor

Concentrate loading test

Coating thickness test

Flatness test

Salt-spray test

Certificates of Majet raised floor

Exhibition of Majet raised floor

Advantages of encapsulated woodcore Raised Floors

Improved Airflow and Ventilation

One of the primary benefits of raised floors is the enhanced airflow and ventilation they offer. This is particularly crucial in environments with sensitive electronic equipment, such as data centers.

Accessibility for Cabling and Utilities

Raised floors provide a concealed space for the installation and maintenance of cabling, electrical wiring, and plumbing. This accessibility simplifies upgrades and repairs, reducing downtime.

Enhanced Flexibility in Space Usage

The modular nature of raised floors allows for easy reconfiguration of interior spaces. This adaptability is especially valuable in office settings where layouts may need frequent adjustments.

How to maintain encapsulated woodcore raised floor?

In order to get better use results and extend the service life of the raised floor, correct daily cleaning and maintenance are important.

1.Carefully read the use and maintenance instructions

Provided by the raised floor manufacturer and follow them. Floors made of different materials may have different maintenance methods.

2.Use shoe covers and foot pads

Placing floor mats at the door of the room can effectively reduce dust and debris from being brought into the room, reducing the frequency of cleaning of the raised floor.

If possible, you can use protective tools such as shoe covers to reduce dust and debris and reduce the scratching of the soles on the floor. Especially helpful for the maintenance of PVC veneer.

3.Prevent overloading

Please do not place particularly heavy furniture or equipment directly on the raised floor. You can use a load-bearing base to distribute the weight, or use other means of proper load distribution.

4.Clean regularly

During use, the raised floor needs to be cleaned regularly depending on the use environment. You can use a soft-bristled brush or vacuum cleaner to remove dust and debris from the surface to reduce particles from repeatedly scratching the floor.

When necessary, the floor needs to be deep cleaned to remove stubborn stains. Be careful not to use harsh chemicals or abrasive cleaners as they can cause damage to the floor. It is recommended to use professional floor cleaners.

5.Anti-static finish

When the floor uses an anti-static finish, its anti-static performance needs to be tested regularly.

6.Leakage problem

If the raised floor is used in an area prone to leaks or spills, please check regularly for leaks. Water can cause damage to the raised floor and supporting structures, so leaks need to be resolved promptly.

7.Professional inspection

Regularly check the situation of your raised floor. If there is damage, such as loose tiles, damaged edges or corrosion of accessories, it needs to be repaired in time. If it cannot be repaired, please replace the bad parts.

FAQs of encapsulated woodcore raised floor

Q1.Why Choose encapsulated woodcore Raised Floor?

1.Flexibility and Customization

One of the primary reasons architects and builders are turning to steel raised floors is their unparalleled flexibility. These floors allow for easy customization to meet the specific needs of a space, making them ideal for environments with evolving requirements, such as office spaces.

2.Accessibility and Maintenance

The space beneath steel raised floors, known as the plenum, serves as a concealed pathway for cables, electrical wiring, and ventilation systems. This not only streamlines the aesthetic appeal of the space but also facilitates easy access for maintenance and upgrades, minimizing downtime.

3.Improved Indoor Air Quality

Steel raised floors contribute to better indoor air quality by promoting efficient air circulation. The plenum acts as a channel for air movement, reducing the risk of stagnant air and fostering a healthier environment, particularly crucial in spaces like data centers.

4.Versatility in Applications

Whether it’s an office, data center, cleanroom, or laboratory, steel raised floors adapt seamlessly to various applications. Their versatility makes them a preferred choice in diverse industries where the need for adaptable and functional spaces is paramount.

In essence, steel raised floors serve as a foundation for innovation in design and functionality, offering a dynamic solution that addresses the evolving demands of modern architecture.

Q2.How encapsulated woodcore Raised Floor Compare to Traditional Flooring?

In the fourth part of our series on steel raised floors, we embark on a comparative analysis, pitting these innovative flooring solutions against traditional alternatives. By examining factors such as installation, maintenance, and adaptability, we aim to showcase the distinct advantages that set steel raised floors apart.

1. Installation Process: Speed and Efficiency

When it comes to the installation process, steel raised floors stand out for their speed and efficiency. Traditional flooring methods often involve time-consuming processes, including the curing of adhesives and setting times for materials. In contrast, steel raised floors, with their modular design, can be installed more swiftly, minimizing construction timelines and reducing associated costs.

2. Flexibility and Customization

One of the defining features of steel raised floors is their flexibility and customization capabilities. Traditional flooring methods, such as glued-down carpeting or hardwood, lack the adaptability needed for dynamic environments. Steel raised floors, with their modular panels, allow for easy reconfiguration to meet changing needs, providing a level of versatility unmatched by traditional alternatives.

3. Accessibility for Maintenance and Upgrades

Maintenance considerations play a crucial role in flooring choices. Traditional flooring, when damaged or requiring maintenance, often involves extensive and intrusive procedures. Steel raised floors, on the other hand, excel in this aspect. The plenum space beneath allows for easy access to underlying infrastructure, simplifying maintenance procedures and reducing downtime.

4. Cost Considerations and Long-Term Savings

While the initial cost of steel raised floors may seem higher than some traditional flooring options, it’s essential to consider the long-term savings they offer. The efficiency of installation, reduced maintenance costs, and adaptability contribute to a higher return on investment over the life of the building.

5. Environmental Impact

In an era where sustainability is a top priority, the environmental impact of flooring choices cannot be overlooked. Traditional flooring materials may involve adhesives and finishes with volatile organic compounds (VOCs), contributing to indoor air pollution. Steel raised floors, with their focus on improved indoor air quality, align with sustainable building practices.

This comparative analysis underscores the distinct advantages of steel raised floors over traditional flooring methods, positioning them as a forward-thinking and practical choice for modern construction and design.

FAQs of factory raised floor

Q1.What is your MOQ?

A: 100pieces each type

Q2.What is the loading quantity in one 20GP?

A:1100-1500pieces,depending on the raised floor type.

Q3.When is your delivery time?

A: 30days after receiving the prepayment.

Q4.What is your package?

A:packed in wooden pallet,covered with plastic film.

Q5.What is your payment term?

A:T/T,L/C,Western Union.