PRODUCTS

FRC Raised Floor Inorganic Cement Floor 500×500 Office

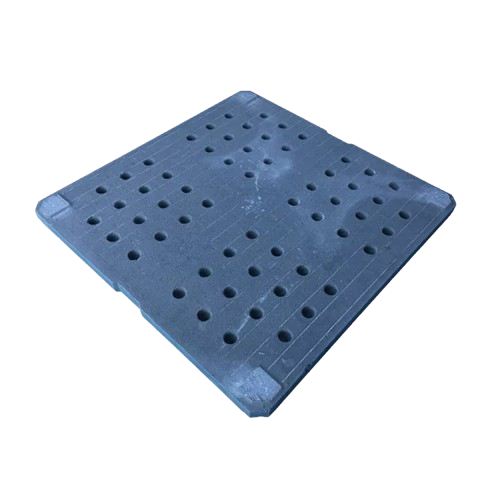

Structure of FRC inorganic cement raised floor

What Are Inorganic Cement Raised Floors?

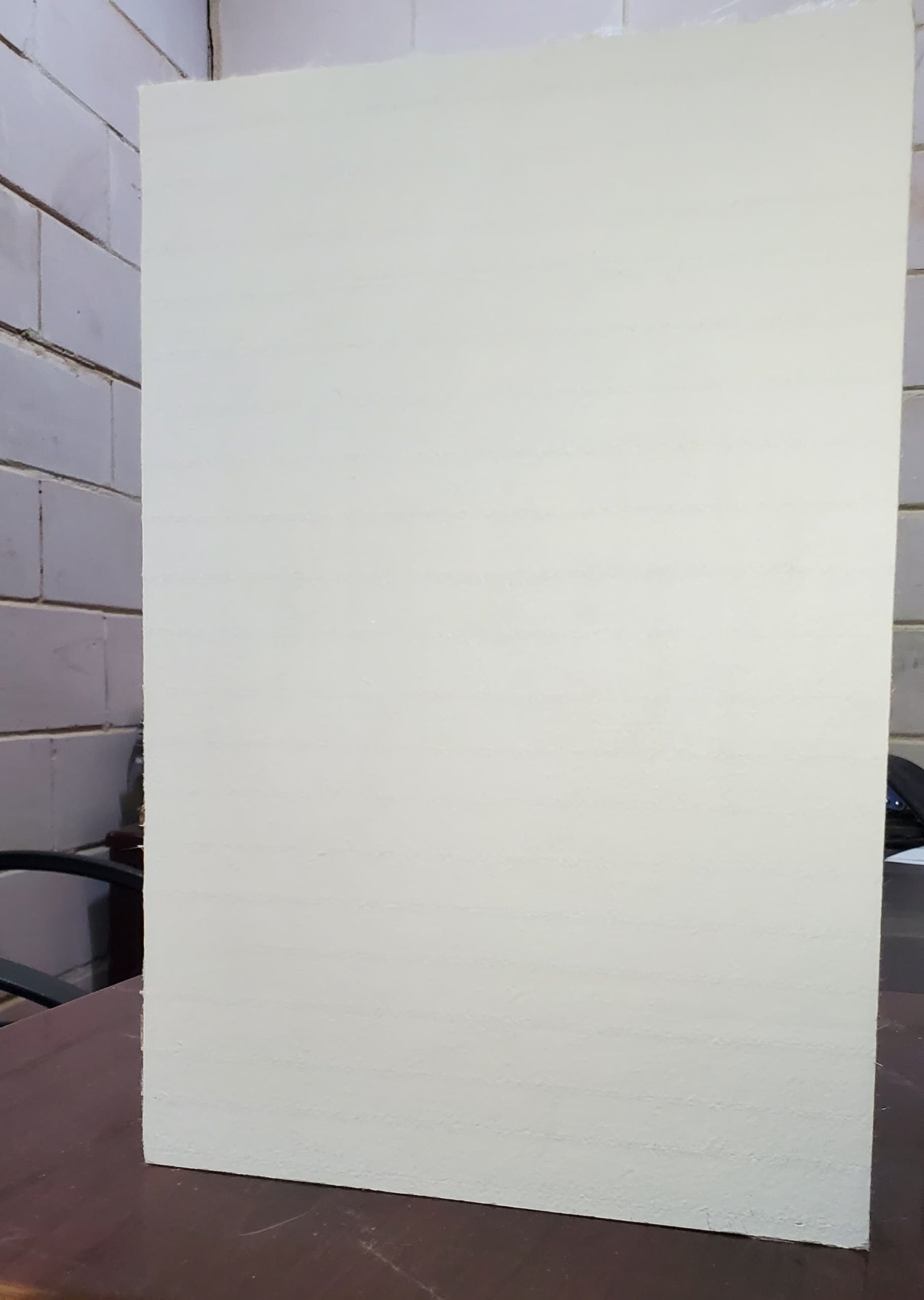

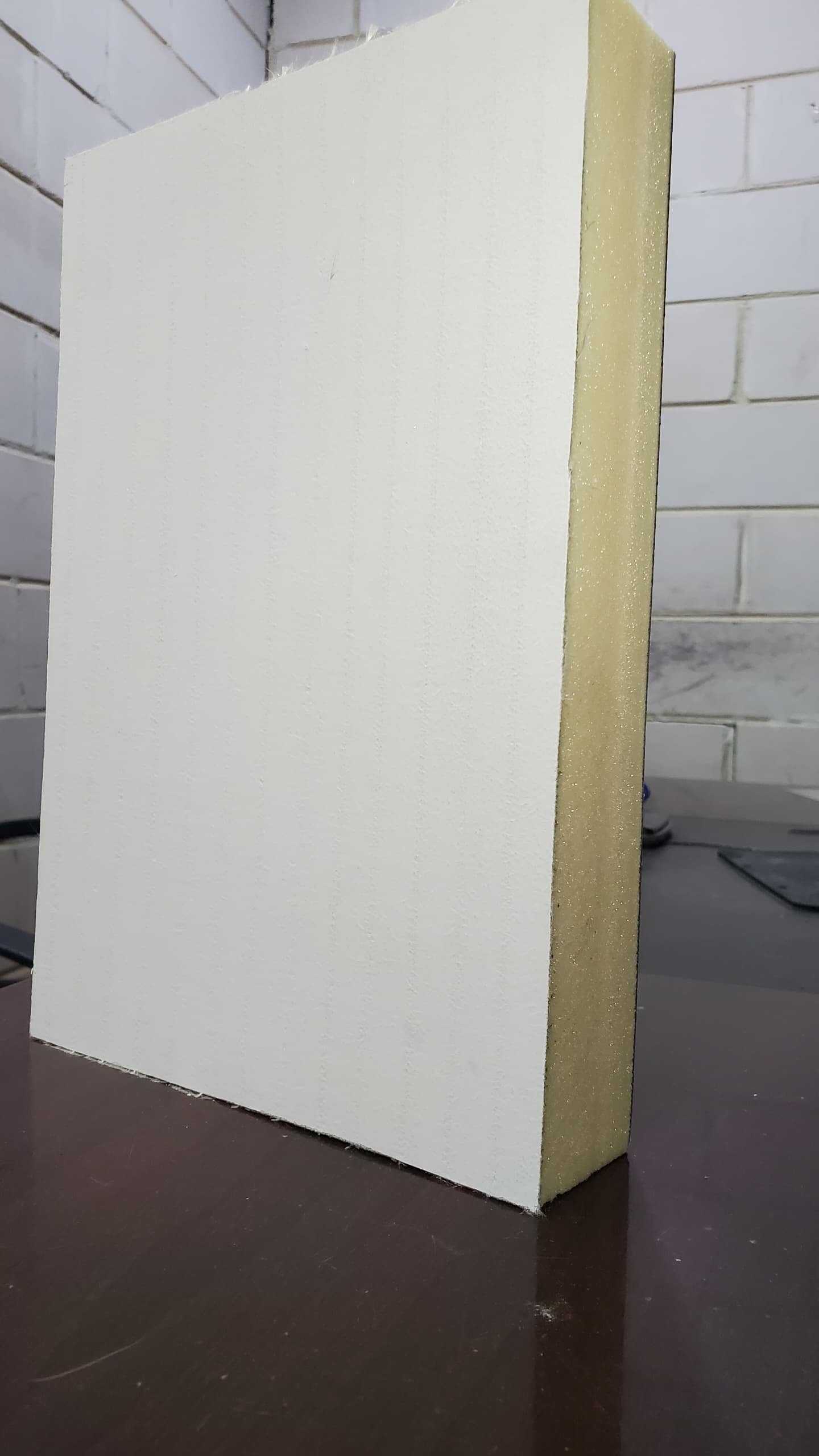

FRC access floor is made of silicate, inorganic fiber, mineral fiber, quartz sand, etc, once-molded after high pressure.

The panel has no volatile toxic chemicals and radiation, and can be decomposed complerely. Its service time is the building.

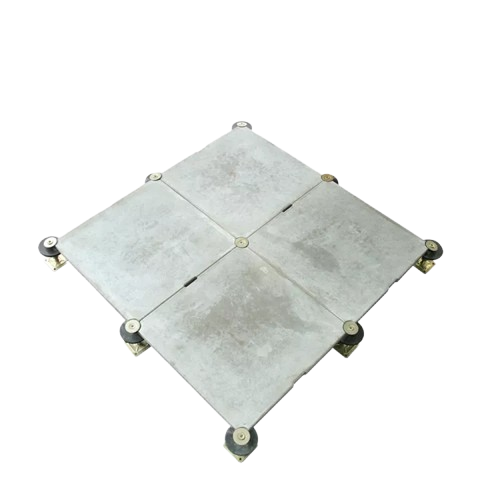

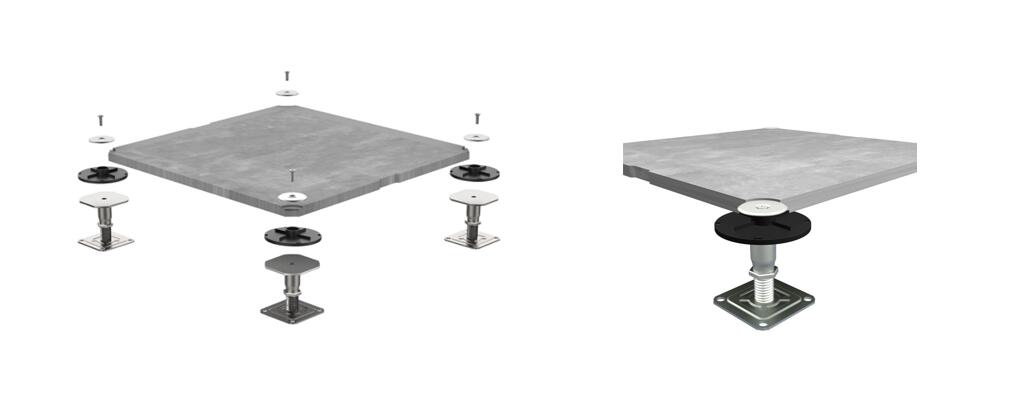

Each panel has hole for wires, four corners supported by pedestals, with no stringers. Good flatness and solid feeling.

Finishes can be laminate flooring, PVC, carpet, etc.

Inorganic cement raised floors represent a paradigm shift in flooring technology. Unlike traditional flooring systems, these floors incorporate high-strength cementitious panels supported by a grid of pedestals, creating a raised structure. This innovative design serves a dual purpose – providing a sturdy surface while creating a space beneath for the seamless installation of utilities.

Key Components and Functions

The components of inorganic cement raised floors work in harmony to deliver exceptional performance. The high-strength materials in the panels ensure durability, while the elevated structure facilitates easy access to the space underneath. This unique feature not only accommodates the installation of cables and airflow systems but also enhances the overall structural integrity of the building.

Underfloor System FRC inorganic cement raised floor

Galvanized Steel pedestal

Specification of FRC inorganic cement raised floor

Installation Process of FRC inorganic cement raised floor

Installing raised floors involves a systematic approach to ensure stability and functionality. The process includes preparing the subfloor, assembling the support structure, and securing the panels in place.

Step-by-Step Guide to Installing Raised Floors

Subfloor Preparation:

Ensure the subfloor is clean, level, and free from debris.

Grid Assembly:

Construct the support grid according to the design specifications.

Panel Installation:

Secure the panels onto the grid, ensuring a snug fit.

Finishing Touches:

Complete the installation with trim and edge pieces for a polished look.

Installation tools of raised floor

Raised floor electrical screwdriver

Installation Vedio of FRC inorganic cement raised floor

Features of FRC inorganic cement raised floor

1. long usage life :

The cornerstone of inorganic cement raised floors is their remarkable durability. Crafted from high-strength materials, these floors are resistant to wear and tear, ensuring a robust and long-lasting foundation for any building.

2. Fire Resistance:

In environments where fire safety is paramount, inorganic cement raised floors shine. Their inherent fire resistance properties make them an ideal choice, providing an additional layer of protection in critical spaces.

3. Green material :

As the world increasingly embraces sustainable construction practices, inorganic cement raised floors stand out. The use of eco-friendly materials not only contributes to green building certifications but also aligns with the growing emphasis on environmental responsibility.

4. Easy to movement and replacement :

The raised structure of these floors offers unparalleled flexibility. Adapting to changes in technology or building requirements becomes seamless, making them a preferred choice for environments that demand adaptability.

5. low price :

While the initial investment may be higher than some traditional flooring options, the long-term benefits and reduced maintenance costs make inorganic cement raised floors a cost-effective choice over the lifespan of a building.

Production process of FRC inorganic cement raised floor

Process: Cutting-forming-welding-phosphating and spraying-filling cement-drying